Industries

Brewing

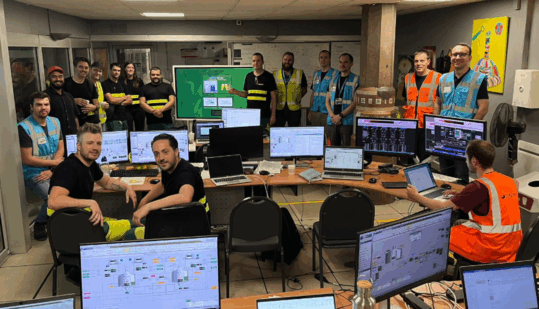

Over the past three decades, our experience and expertise in the brewing industry have positioned us as a leading independent process control system integrator.

ABOUT

We have delivered thousands of automation, electrical engineering, power distribution, and digital transformation projects and solutions for more than 280 breweries on six continents .

Our comprehensive understanding of beer production technology and the equipment of all generations enables us to effectively address client challenges and enhance their production processes.

For years, we have been a reliable partner of the world’s largest brewing groups, such as Heineken, AB InBev, Molson Coors, Castel Group, Asahi, Carlsberg, as well as numerous independent breweries, and major brewing industry equipment manufacturers such as Meura, Krones, Künzel, GEA, Pentair, Ziemann Holvrieka, and many others.

Case studies

Transformative solutions in action

Numerous practical examples of providing customised solutions for small and large production complexes confirm our expertise and knowledge.

Automation system migration

Ho Chi Minh City, Vietnam

Customer: Heineken Vietnam Brewery Limited Company

Project type: Migration

Site:Brewery Hoc Mon located in Ho Chi Minh City, Vietnam, which produces more than 7 million hl of beer annually, is considered the flagship of Heineken Vietnam. One of the most complex, yet well-organised sites, featuring three brewhouse lines, ten tank rooms, two filters, and seven packaging lines.

Revamping project

Bracongo, Kinshasa, DR Congo

Order by: Castel Group

Type of project: Revamping

Site:

BRACONGO (Boissons renouvelables du Congo) is a Congolese industrial company in the agri-food sector specializing in the production, marketing and distribution of food beverages (beers, sweetened soft drinks and water), and also in the trading of wines, spirits and fruit juices. With its production plant in Kinshasa and 14 distribution centres across the country, Bracongo employs nearly 2,000 people (directly and indirectly), produces and sells more than 1.5 million hectolitres of beverages, and has over 50 years of experience serving Congolese consumers. Its product portfolio currently includes seven beer brands and six soft drink brands (sweetened carbonated drinks, energy drinks, and water).

Brewery expansion and migration

Testimonials

What our clients say

our clients

Our Clients section showcases the diverse partnerships and trusted relationships we've built, underlining our commitment to excellence and customer satisfaction.