Industries

Steel

We know how to address the challenges of the complex steel industry and ensure its reliability and safety.

About

Our innovative solutions are enhancing different areas of steel production, leading to significant and undeniable improvements across the board:

Material preparation:

• Raw material handling

• Scrap yard

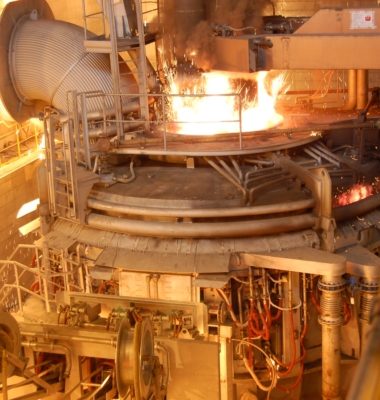

Melt shop:

• Electric arc furnace

• Ladle metallurgical furnace

• Vacuum degasser

• Vacuum oxygen degasser

• Stoppers

• Mold hydraulic oscillator

• Billet casting machine

• Bloom casting machine

• Mechanical soft reduction

• Marking machine

Environmental facilities:

• Dust extractions with Fabric, ESP and Hybrid filters

• Dust conveying and storage

• Gas emission reduction, Dry Sorbent Injection

Case Studies

The practical examples showcasing a wide range of possibilities for modernizing the steel industry.

Steel industry references

The most significant projects in the steel processing delivered to our steel industry clients

our clients

Our Clients section showcases the diverse partnerships and trusted relationships we've built, underlining our commitment to excellence and customer satisfaction.